This technique is rarely used today. Artwork should be received by plant operators 60 days before the posting date. Rendered by skilled artists and painted, the artwork scale should be 3/8” or 1/2” = 1’.

This is the most common technique for producing bulletins. Durable and long-lasting flexible vinyl faces present a uniform appearance with good color and art quality. Vinyl or plastic bulletins must be supplied to plant operators at least 10 working days prior to the posting date. The material is usually produced on one sheet and stretched over the face of the structure. A four-inch pole pocket is contained within the bleed on all four sides are required.

The vinyl-coated polyester weave and polyethylene plastic used as a bulletin substrate varies in weight and density, depending on its application. Typically, billboard flex is a lightweight material; its strength is derived from the structure it wraps. Usually, it is not fire-retardant and is between eight and 12 oz. per square yard. There is a heavier 18 oz. material which is fire-retardant and is typically used for interior signage and in situations where flame spread and smoke density are an issue.

All inks are weatherproof and waterproof with sufficient UV protection.

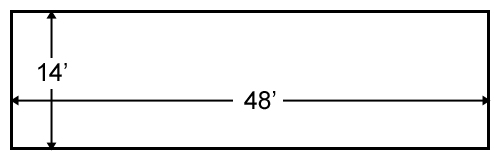

The layout size for 14’ x 48’ bulletins is 7” x 24”, scaled to 1/2 ”x 1’. A tissue overlay is used to note special embellishments and colors and, if a photograph is used in the design, an 8” x 10” (or larger) color photograph should be provided with a color copy of the layout.

Digital files should be supplied at 300 dpi with a printout. The preferred layout sizes are 3/8” or 1/4” scale. Screen and printer fonts should be included as well as all image files. Low resolution images are acceptable for placement only. Supply original transparencies or hi-resolution scans for any artwork. All images and art files provided should be saved in CMYK mode, and as EPS or TIFF files with an accompanying color printout of the layout.

To increase the impact of bulletins, extensions (cutouts that extend beyond the basic shape of the structure) are often used. Extensions or cut-outs may be added around perimeters often with a one-time charge per square foot and a once-a-month maintenance charge. Depending on local restrictions, extensions or cut-outs may be added from 5’ to 5’6” on top, 2’ on the side and 1’ on the bottom. Extra space cost is comparable to print media foldouts or inserts. Check with local out of home operators for market-specific rules and regulations.

Published: September 12, 2022